FlexMFG Job Shop

FlexMFG Job Shop is a feature-rich module designed for engineer to order operations of all sizes. It inter-operates with Acumatica’s Distribution Edition, is attractively priced and competes with Macola and other ECi offerings, and in many instances Epicor.

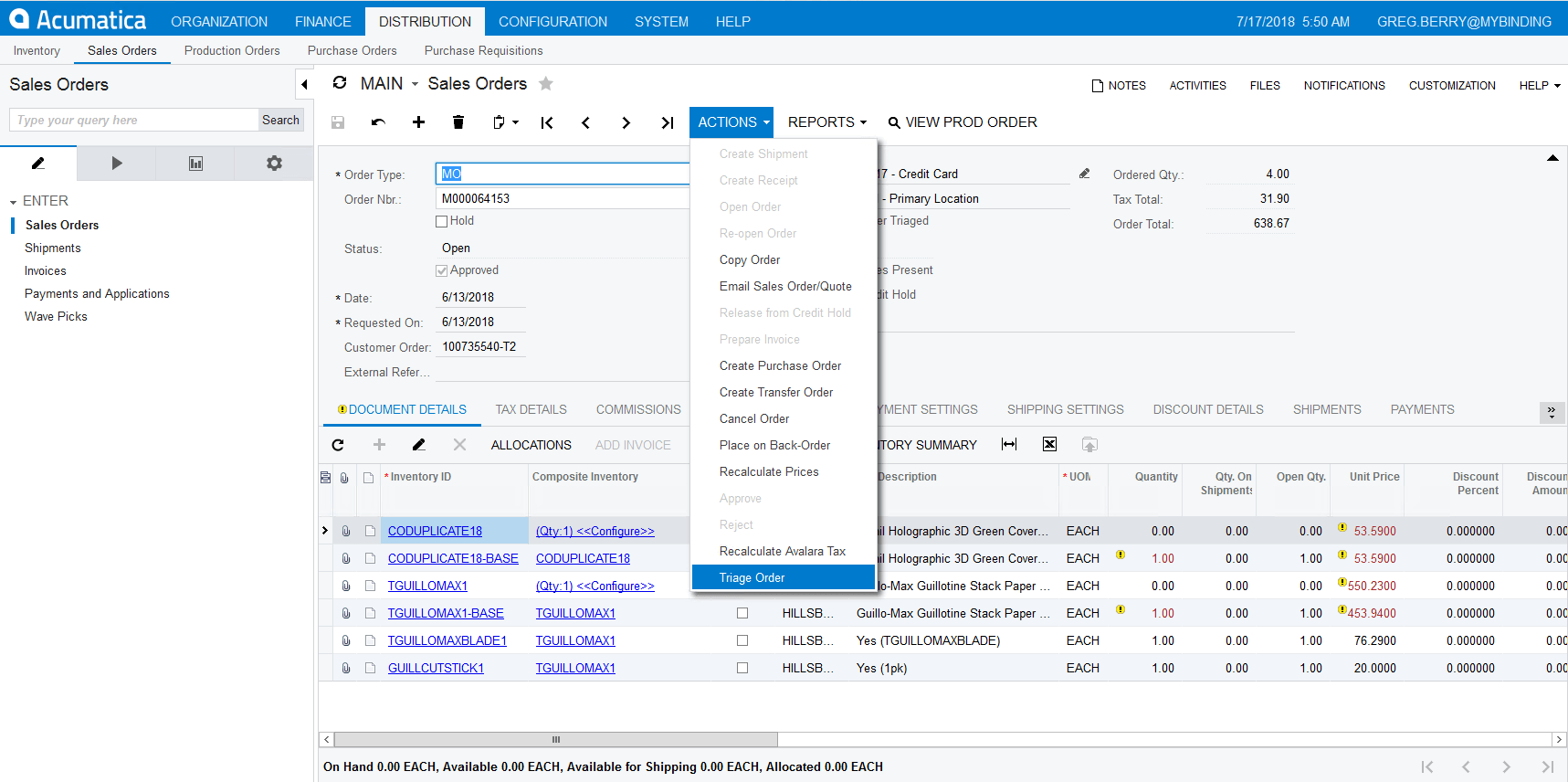

Features of note include a dynamic bill of material which may be of unlimited indentures, serialized at all levels/components, and modifiable at any time during the bidding, planning OR production cycles. The MRP logic aggregates all demand across all work orders consolidating vendor PO’s. Actual labor maybe recorded and billed prior to work order completion; partials are supported. Also, specs, drawings, videos and the like may be appended to bids, jobs and change orders.

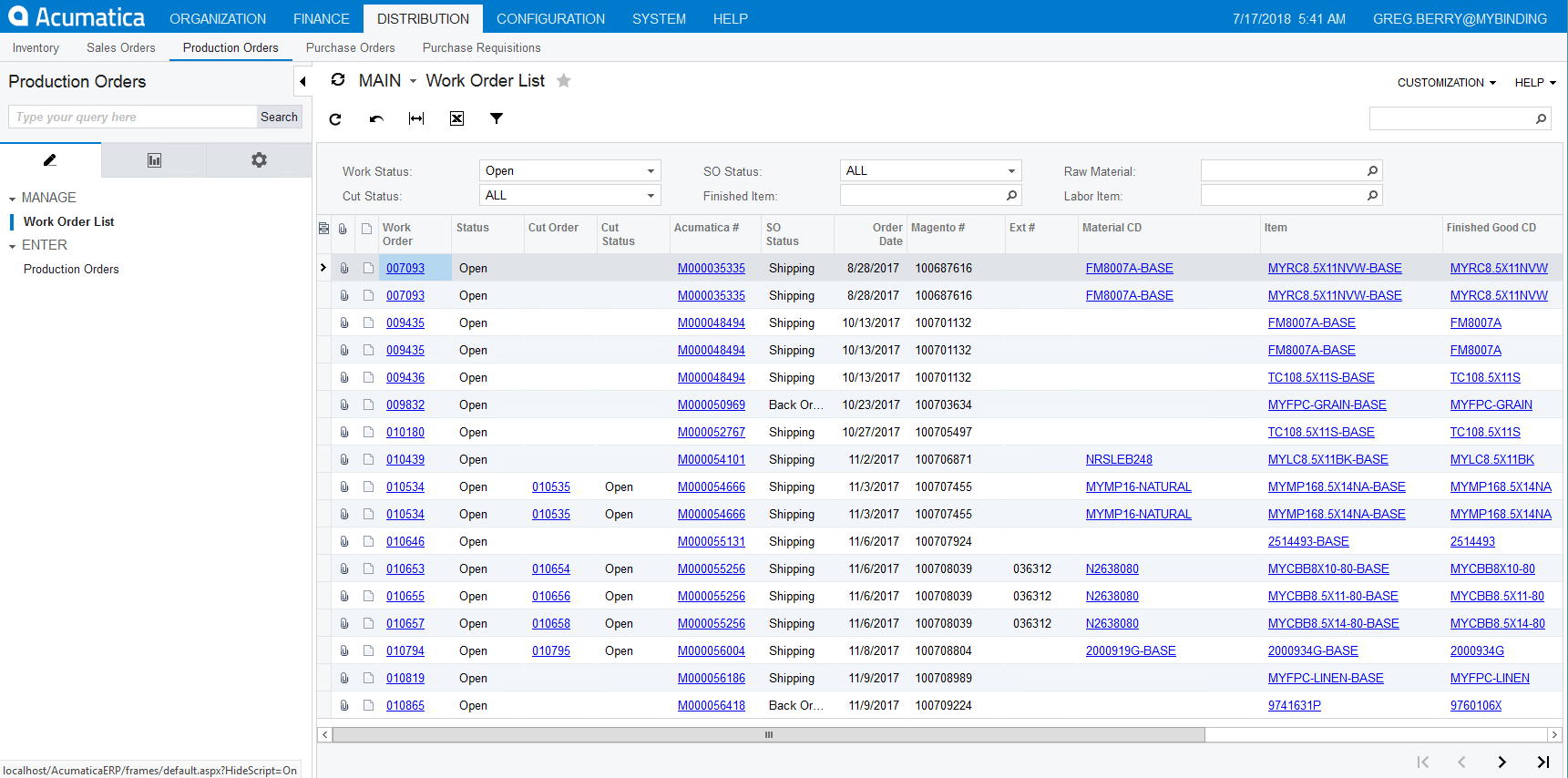

FlexMFG incorporates Acumatica's dashboards and side panels, and MRP interoperates with Acumatica replenishment logic regarding safety stock and EOQ. Users especially like FlexMFG’s scanning function with lets workers enter time without consuming a named user license; and the scheduling tool which instantaneously determines whether labor is available when planning jobs for a given day, week, month, etc. – for all operations or per department.

Key features

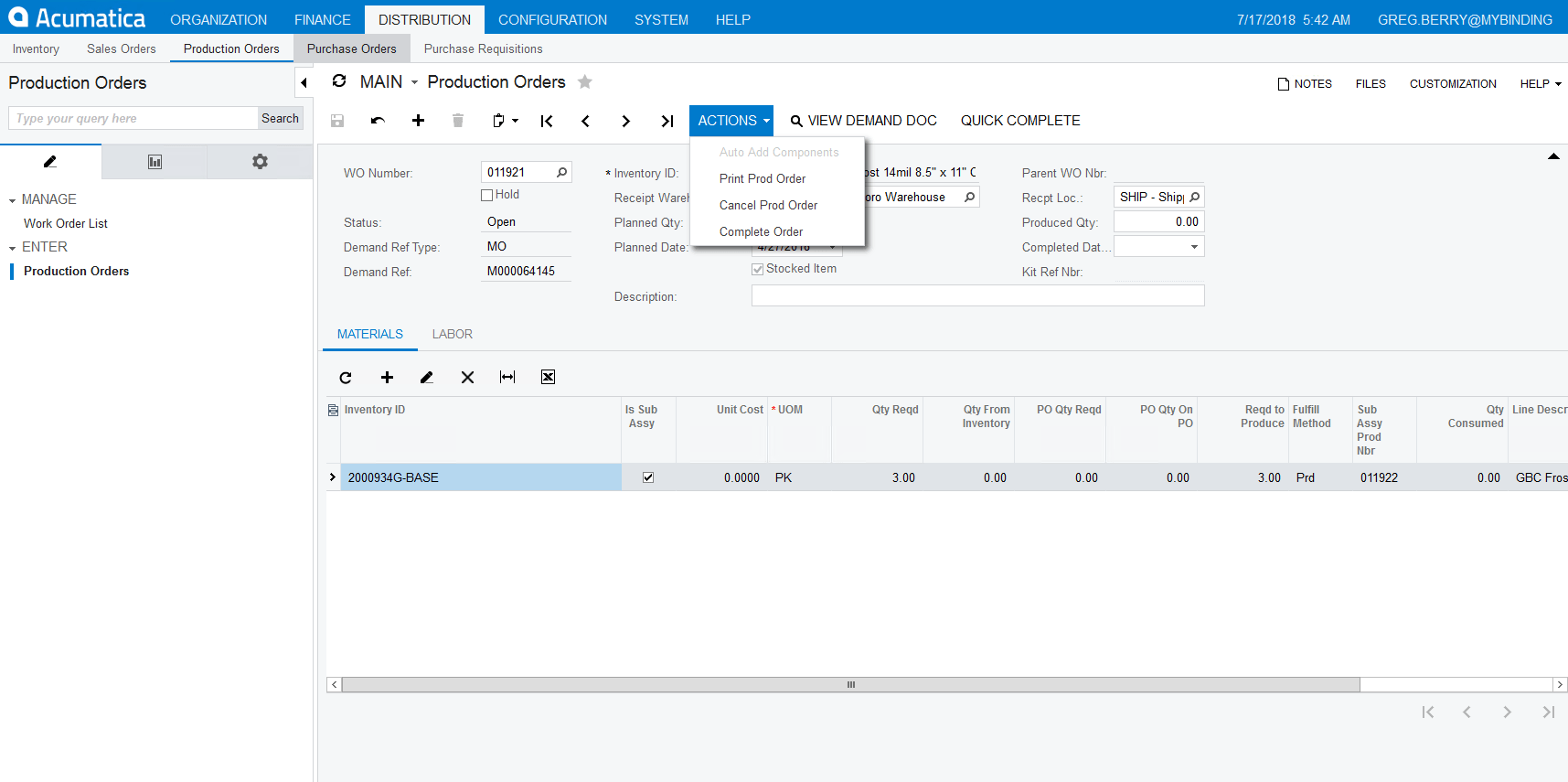

- Dynamically Create Work Orders and BOMs of Unlimited Indentures

- Create BOMs from Scratch or “Same As, Except.” Modify BOM at Any Time in Planning or Production

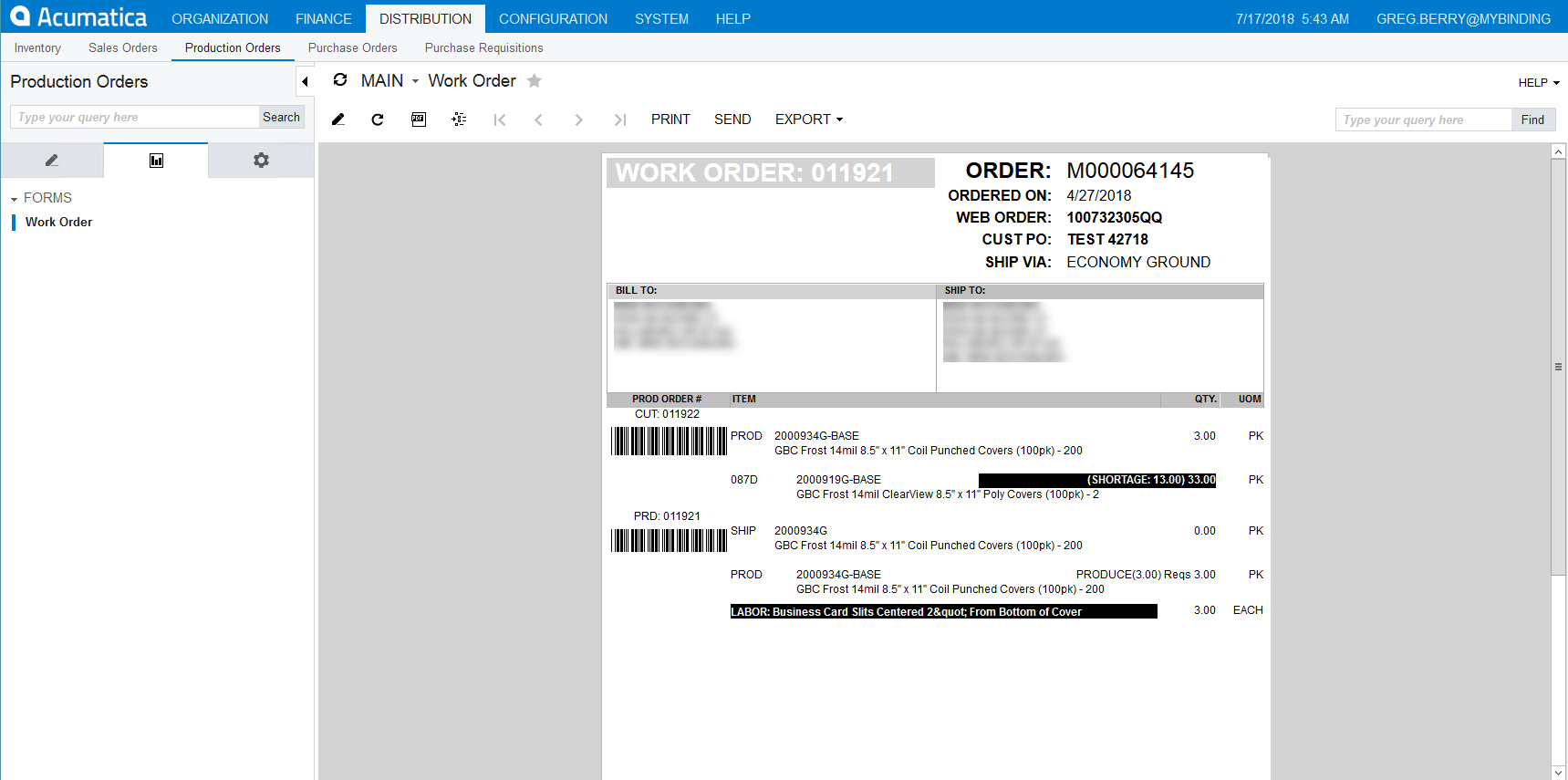

- May Serialize Finished Good, Sub-Assemblies and Components

- Bid Jobs Including Margin Analyses to Help Determine Sales Price

- BOM includes both Material and Labor: Calculate Cost of Goods Sold

- Captures Scrap to Compare As-Planned and As-Built COGS

- Generates Work Order Documents For Assemblers/Production. Functions as “Traveler”

- Includes MRP to Calculate Material Requirements and Generate Purchase Orders

- Capture Actual Labor (per Operation) and Invoice Labor at Any Time. (ETO Environment)

- Includes Drag ‘n Drop Schedule Board and Labor Capacity Bar Chart Widget Dash Boards Provide Production/Purchase Status

- Perfect for Small Business Edition (Allows Unlimited User Labor Capture)

About Advanced Solutions and Consulting Co

Advanced Solutions & Consulting Co. (ASC) is a founding Acumatica VAR with MVP status. We deliver ISV solutions that save serious time and money for supply chain and accounting applications. Our solutions are written in native Acumatica xRP. They address complex ERP requirements extending Acumatica’s market breadth and competitiveness.

ASC augments Acumatica with elegant solutions that monitor and automate ERP functions to improve Acumatica’s competitive landscape and save customers (and their VAR’s) serious time and money.

Resources

Customer Reviews

Your insights are valuable, be the first to rate this solution.

- Help your peers. If we all provide feedback on our business solutions, our collective wisdom will help take the pain out of purchasing decisions for everyone.

- Share feedback. Using a solution that has made your job easier or provided benefits to the team? Make your voice heard.

- Earn recognition. Your detailed, balanced reviews of the solutions that you know inside and out can position you as an expert.