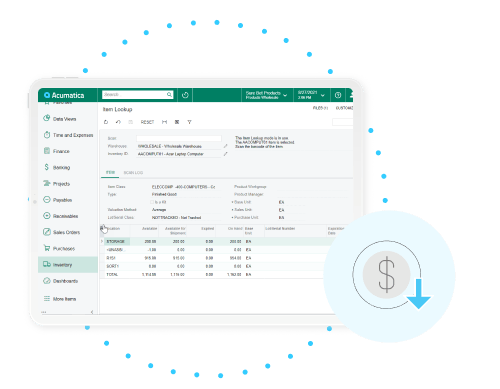

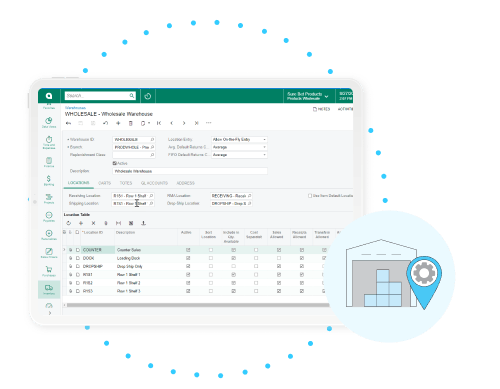

Order management is the process of managing orders from when they’re received to when the orders are fulfilled. Like inventory management software, order management software can be utilized by businesses of all sizes. Unlike inventory management software, order management software is for businesses that carry inventory and for those that do not.

Order management software provides users with Sales Order, Purchase Order, and Requisition Management capabilities, automated requisitioning, integrated workflows, and more. A business can utilize order management software alone or in conjunction with inventory management software.

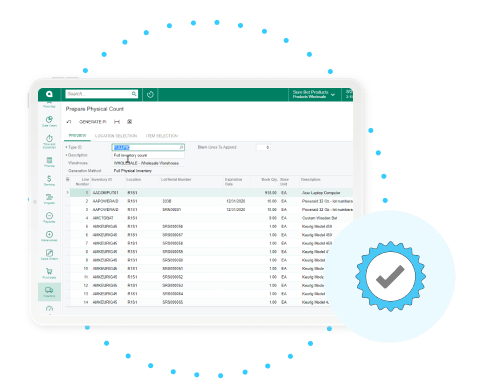

“Acumatica handles inventory so much better than our old system. This is a big-time saving for us to see live inventory availability across our three different locations and not have to resort to various spreadsheets or wander through our yards of products like we did before.” – Steve Slaughter, President/CEO, Frederick Block, Brick & Stone

Canada (English)

Canada (English)

Columbia

Columbia

Caribbean and Puerto Rico

Caribbean and Puerto Rico

Ecuador

Ecuador

India

India

Indonesia

Indonesia

Ireland

Ireland

Malasya

Malasya

Mexico

Mexico

Panama

Panama

Peru

Peru

Philippines

Philippines

Singapore

Singapore

South Africa

South Africa

Sri-Lanka

Sri-Lanka

Thailand

Thailand

United Kingdom

United Kingdom

United States

United States