Manufacturing Management

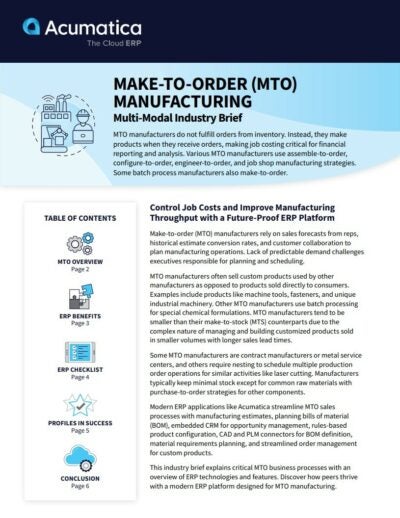

- Real-time insights from every department

- Access to data anytime, anywhere, on any device

- End-to-end control over production

- Support for multiple manufacturing methodologies

- Automated order management and streamlined procurement

Comprehensive manufacturing ERP with extensive functionality and breadth.

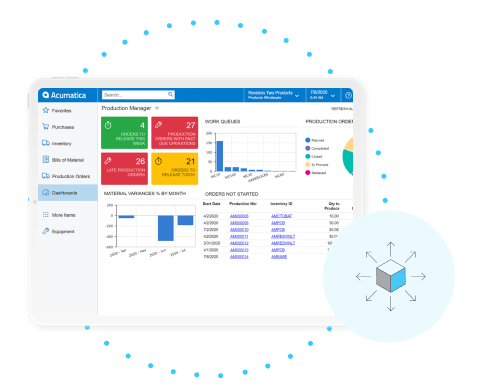

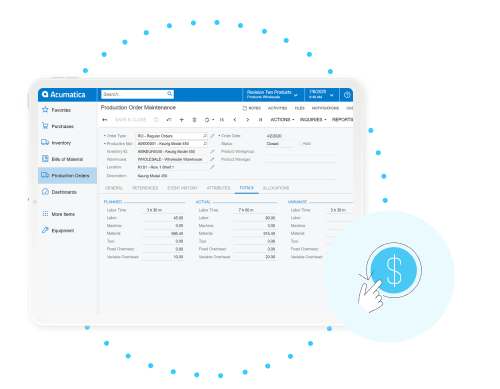

Acumatica Manufacturing Edition delivers unparalleled depth with an extensive suite of connected manufacturing business applications for production, estimating, engineering, material planning, scheduling, and product configuration for both discrete and batch process production.

Unique breadth in a manufacturing product is achieved by out-of-the-box document management, customer relationship management (CRM), project accounting, commerce, expense management, payroll, and field service.

Grow and evolve your business with a scalable, secure, and future-proof cloud platform.

Utilize modern business technologies such as cloud computing, big data and analytics, additive manufacturing, robotics, augmented and virtual reality, and the Industrial Internet of Things for streamlined processes and meaningful insights into manufacturing operations now and in the future.

Leverage enterprise-grade security and SOAP or REST APIs to integrate extended business applications such as Manufacturing Execution Systems (MES), Electronic Data Interchange (EDI), CAD/PLM, Rental, Point of Sale, and more.

Streamline manufacturing processes for a competitive advantage and better customer experience.

Improved manufacturing processes reduce scrap, limit costly changeovers, and improve labor efficiency, providing a distinct competitive advantage with lower pricing, higher profits, on-time shipments, and better product quality -- resulting in more satisfied repeat customers.

Improve communications using powerful Business Events to automate customer communications, notifications, and document transmittal.

Empower customers with a self-service portal to view order status, check inventory levels, place new orders, and configure products online.

Canada (English)

Canada (English)

Colombia

Colombia

Caribbean and Puerto Rico

Caribbean and Puerto Rico

Ecuador

Ecuador

India

India

Indonesia

Indonesia

Ireland

Ireland

Malaysia

Malaysia

Mexico

Mexico

Panama

Panama

Peru

Peru

Philippines

Philippines

Singapore

Singapore

South Africa

South Africa

Sri Lanka

Sri Lanka

Thailand

Thailand

United Kingdom

United Kingdom

United States

United States