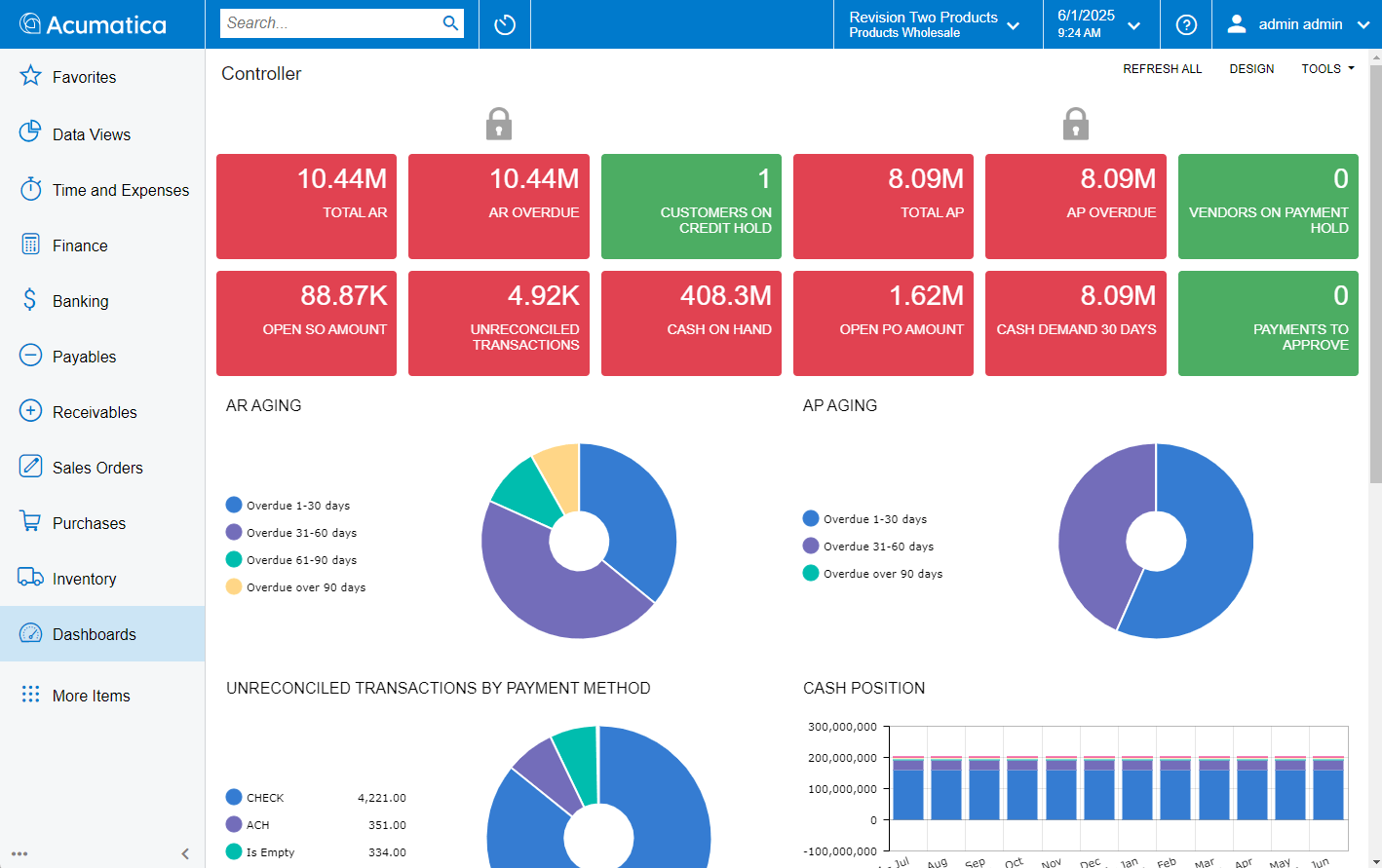

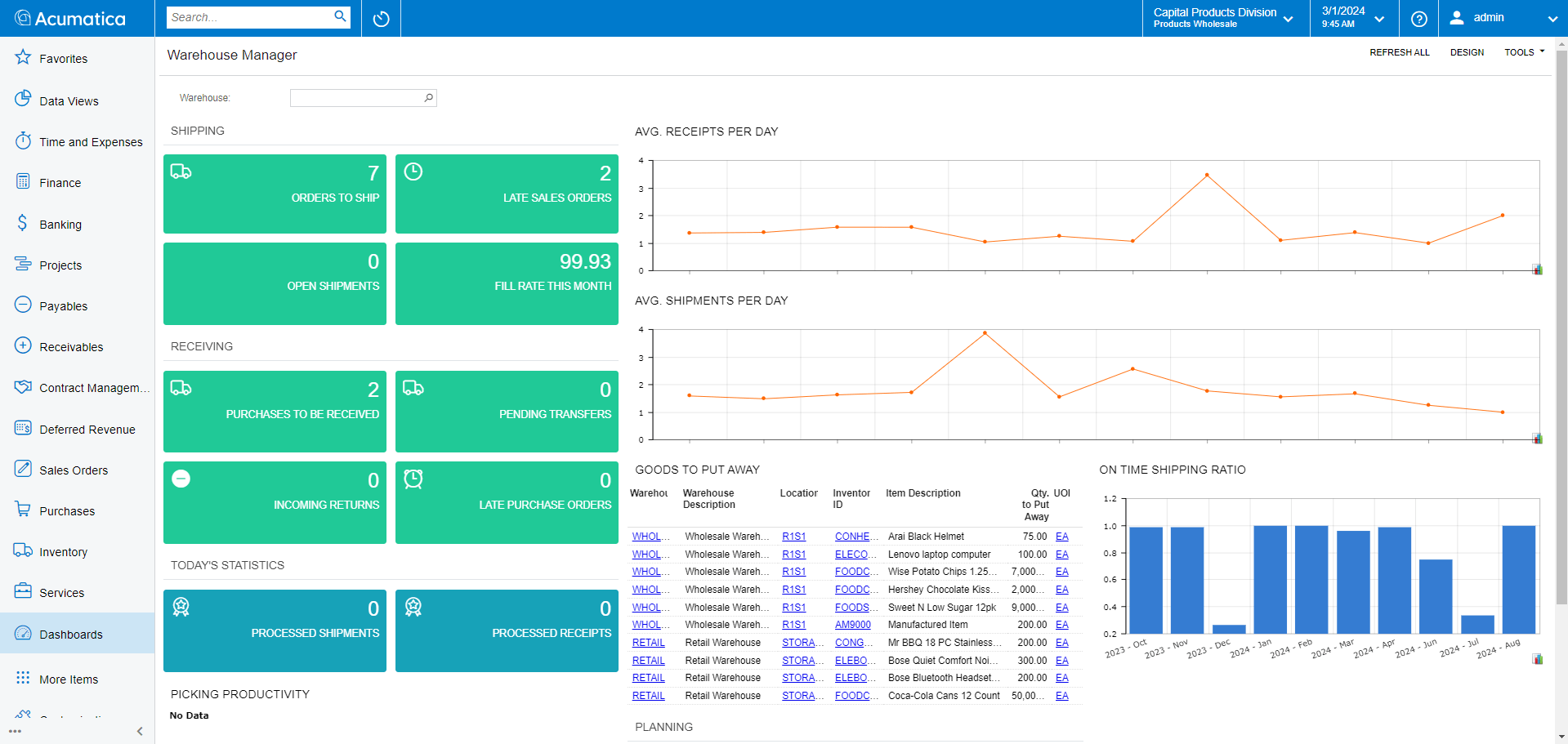

Improve inventory management and warehouse operations for faster order processing and happier customers with a modern business system.

- Kitting with Disassembly

- Serial and Lot Tracking

- Matrix Items

- Embedded WMS with Barcoding

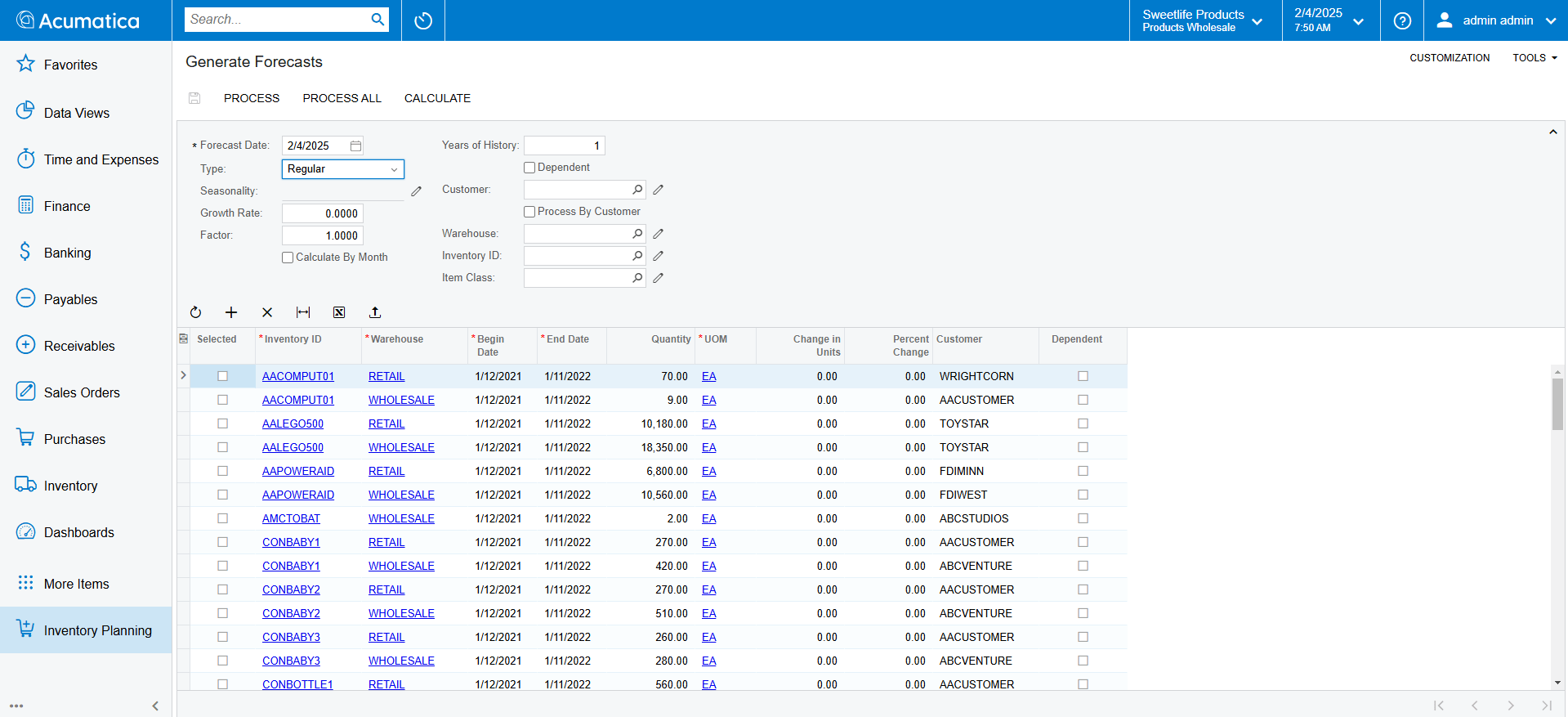

- Demand Planning

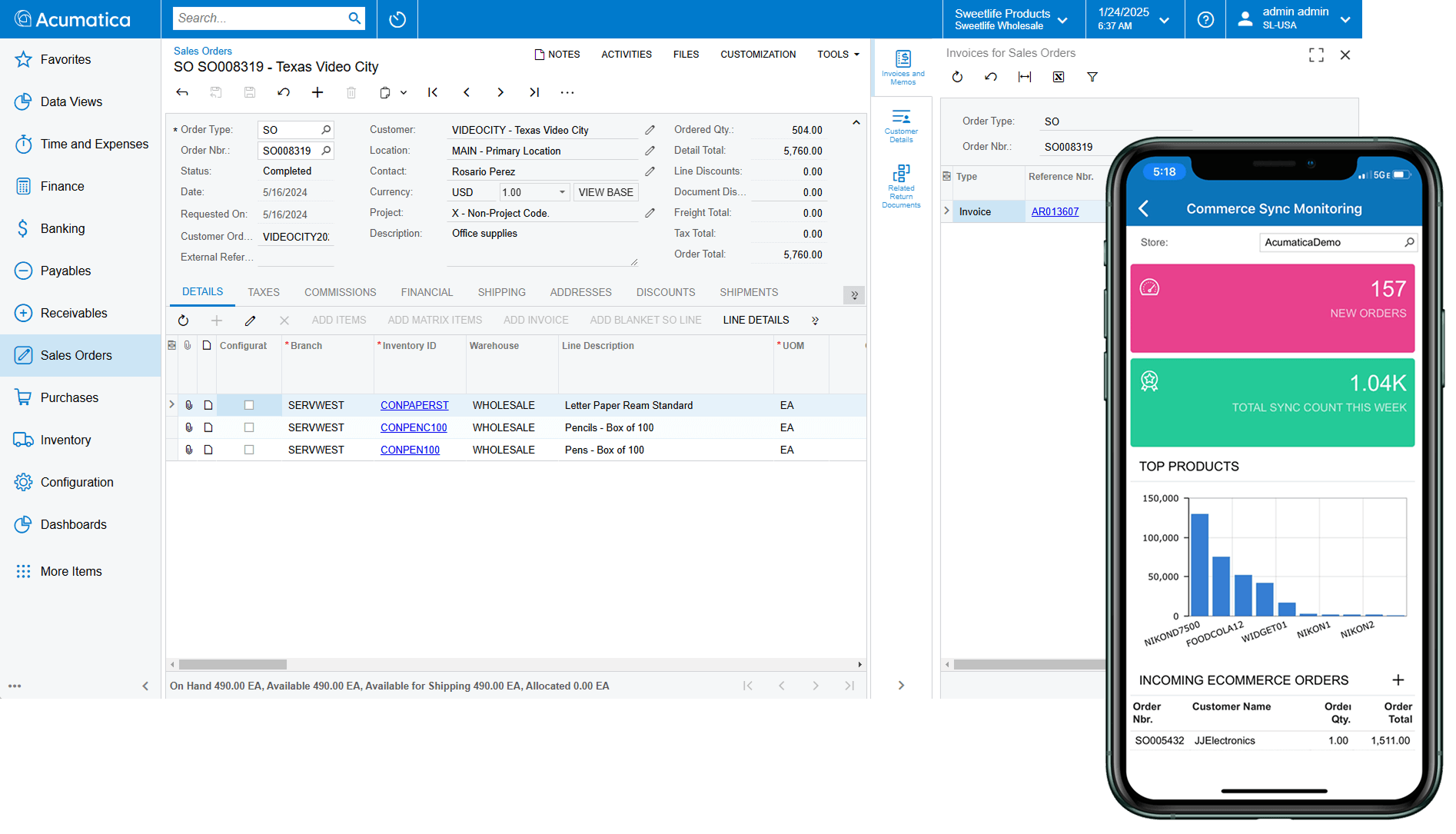

- Connected Shipping and EDI

Canada (English)

Canada (English)

Colombia

Colombia

Caribbean and Puerto Rico

Caribbean and Puerto Rico

Ecuador

Ecuador

India

India

Indonesia

Indonesia

Ireland

Ireland

Malaysia

Malaysia

Mexico

Mexico

Panama

Panama

Peru

Peru

Philippines

Philippines

Singapore

Singapore

South Africa

South Africa

Sri Lanka

Sri Lanka

Thailand

Thailand

United Kingdom

United Kingdom

United States

United States